產品中心

Product Center

產品信息

4、絕不能用低材質墊片取代高材質墊片。避免材料腐蝕或其它原因造成墊片失效。

product information

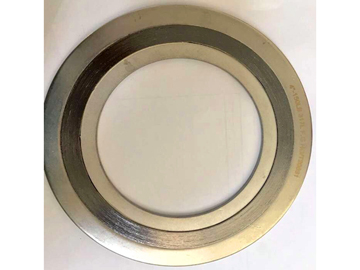

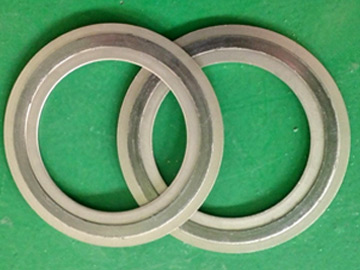

名稱:纏繞墊 規格:DN10~DN600

類型

一:基本型 二:帶內環型 三:帶外環型 四:帶內環和定位環型

填充料

一:石墨纏繞 二:石棉纏繞 三:四氟纏繞

纏繞墊的簡介:

金屬纏繞墊片是目前應用廣泛的一種密封墊片,為半金屬密合墊中回彈性墊片,由V形或W形薄鋼帶與各種填充料交替纏繞而成,能耐高溫、高壓和適應超低 溫或真空下的條件使用,通過改變墊片的材料組合,可解決各種介質對墊片的化學腐蝕問題,其結構密度可依據不同的鎖緊力要求來制作,為加強主體和準確定位, 纏繞墊片設有金屬內加強環和外定位環,利用內外鋼環來控制其^大壓緊度,對墊片接觸的法蘭密封面的表面精度要求不高。

纏繞墊的適用范圍:

石油、化工、冶金、電力、船舶、機械等行業的管道、閥門、壓力容器、冷凝器、換熱器、塔、人孔、手孔等法蘭連接處密封。

適用溫度:-196℃--+870℃(柔性石墨)

≤+250℃ (聚四氟乙烯)

≤+500℃ (特殊石棉)

介質:適用于高溫高壓蒸氣、油、油氣、溶劑、熱煤體油等。

纏繞墊的使用說明:

注意事項

1、墊片的纏繞部分必須介于法蘭密封面之間,不可隨意加寬纏繞部分的寬度,這樣勢必影響螺栓的壓緊力,從而影響墊片的密封性能。

2、基本型墊片^好不要用在凹凸面法蘭上,這是因為基本型墊片在法蘭軸向壓緊力作用下,墊片內圈焊點容易開焊,從而導致墊片失效。

3、在高溫、寒冷或冷熱頻繁交變、振動較大、強腐蝕介質等惡劣工況條件下,用于平面法蘭和凸面法蘭的墊片^好加裝合理材料的內環。

Name: Metal Wound Mat Specifications: DN10 ~ DN600

Types of

A: The basic type two: with the ring type three: with the outer ring four: with the inner ring and positioning ring

Filling material

A: graphite winding two: asbestos winding three: four fluorine winding

Spiral wound pad Introduction:

Metal spiral wound gasket is widely used as a kind of gasket, which is a semi-metal gasket in the spring washer, V-shaped or W-shaped thin strip and a variety of packing alternately wound, high temperature, high pressure And to adapt to the conditions of ultra-low temperature or vacuum, by changing the gasket material combinations, to solve a variety of media on gasket chemical corrosion problems, the structure of the density can be made according to different requirements of the locking force, to strengthen the main and accurate Positioning, winding gasket with a metal ring and outside the positioning ring, the use of internal and external steel ring to control the maximum compression, the gasket contact with the flange sealing surface of the surface accuracy is not high.

The scope of spiral wound pad:

Seals of valves, pressure vessels, condensers, heat exchangers, towers, manholes and handholes in the fields of petroleum, chemical industry, metallurgy, electric power, shipping and machinery shall be sealed.

Suitable temperature: -196 ℃ - +870 ℃ (flexible graphite)

≤ + 250 ℃ (polytetrafluoroethylene)

≤ + 500 ℃ (special asbestos)

Medium: Suitable for high temperature and pressure steam, oil, oil and gas, solvents, hot coal oil.

Metal wound pad instructions for use:

Precautions

1, the gasket winding part must be between the flange sealing surface, not free to broaden the width of the winding part, it will inevitably affect the pressure of the bolt, thus affecting the gasket sealing performance.

2, the basic type of gasket is best not to be used in the convex flange, it is because the basic type gasket in the flange axial compression force, the inner gasket pad easily open welding, resulting in gasket failure .

3, in the high temperature, frequent alternating cold or hot and cold, vibration, corrosive media and other harsh working conditions, the flange for the flat flange and flange gasket is best to install a reasonable material inner ring.

4, must not use low-quality gasket instead of high-quality gasket. Avoid material corrosion or other causes of gasket failure.

- 2018-04-23 > 安裝金屬墊片的基本要求

- 2018-01-15 > 金屬纏繞墊片概述及主要用途

- 2018-01-15 > 密封墊片材料的選擇

- 2017-12-28 > 金屬包覆墊片的詳細介紹

- 2017-12-08 > 聚四氟乙烯墊片 密封墊 耐高溫耐腐蝕

- 2017-11-24 > 高強石墨墊片的介紹

- 2017-11-24 > 法蘭密封及泄漏密封處理方法

- 2017-10-15 > 四氟乙烯墊片^高耐溫多少度?

- 2017-10-10 > 低應力金屬纏繞墊片的技術說明

- 2017-09-13 > 密封盤根的選擇和安裝